Bulk chlorine has long been a Faustian bargain. It keeps pool water sanitized, but it has a lot of inherent problems, the first of which is safety. Many commercial swimming pool owners are looking to step away from chlorine in favor of salt-based water sanitization systems. Safety is a primary reason.

Straight chlorine in any form is unstable. Problems with railroad accidents involving tank cars with chlorine make national news reports – including public safety officials deciding whether to evacuate nearby homes and businesses. Some local governments limit delivery hours or require separate, specially designed storage facilities for chlorine to prevent a large release of chlorine gas.

Mishandling chlorine is a major concern. It’s added to pool water from inside the equipment room, and muriatic acid is added to balance the pH in the water so that the chlorine can work effectively. In all too many cases, the work is done by lifeguards or by people who may not be properly trained in handling both chemicals. Any mishandling can result in the release of chlorine gas in an enclosed area, and effects can be exacerbated if ventilation is inadequate. In a worst-case scenario, mixing chlorine and muriatic acid in the wrong quantities can create a dangerous, noxious gas or cause a fire.

Steve Pearce is vice president of ChlorKing Inc., Norcross, GA, manufacturer of chlorine generators and products for the commercial swimming pool and water treatment industry.

Safety cost factors

The safety problems have cost factors. Scheduling chlorine deliveries for non-business hours can be costly, and building special storage facilities can be costlier. Additionally, costs can escalate if chlorine mishandling causes an incident, including the direct costs associated with having to suspend pool operations.

As a result, saline-based sanitization is gaining more traction.

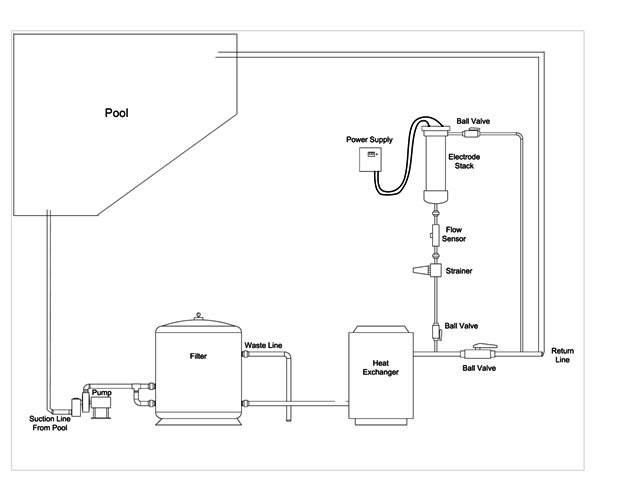

Salt chlorination, known as electrolysis, has been around for nearly 200 years. An electric current is passed through saline water to produce chlorine. In modern systems, small amounts of salt – the same chemical composition of table salt – are added to the pool’s water. The saline water is then passed through a chlorine-generating cell in a self-contained unit in the pool’s pump room. As low-voltage electricity is applied to the metal plates within the cell, the system produces chlorine, which is pumped back into the pool to kill bacteria, algae and germs. After it kills contaminates, it reverts back to salt and is recycled through the chlorinator to begin the process again.

For pool operators who don’t want to add salt directly to the water, an onsite batch chlorine generator may be the solution to replacing chlorine. It produces pH-neutral liquid chlorine (bleach) from salt stored in a feeder in the pump room. It requires no salt in the pool and eliminates the need to add salt and test salt levels. The systems use pool water, which eliminates the need to connect them to freshwater sources. Once the system is installed, the only costs incurred are for salt and electricity.

All saline-based pool-sanitization systems can be safely enhanced with ultraviolet-lighting systems as a secondary form of treatment.