Hydraulics make up a cornerstone to a pool’s or spa’s success. Meant as the technical term for water moving through pipes, equipment and around the pool itself, it carries the key to successful operation, safety and water maintenance. Behind the formulas and charts that we use to engineer a system appropriate to each pool and spa are some base principles. Here, let’s take a look at some of those principles and even common misperceptions about hydraulics.

First, think marbles

Water comprises H₂O molecules that collide with each other and with solid objects. You can easily see this by looking at bottled water: Tip the bottle sideways, and you see H₂O molecules settle together to match the exact shape of the container; dump it out and watch as water molecules collide with the air, separating into droplets.

Pumps don’t suck

While water molecules are happy touching each other, they are not actually attached.

This explains why water can’t be pulled. Insead, it must be pushed through the pipe and even around the inside of the pool. So, despite commonly held beliefs in the pool and spa industry, pumps don’t actually suck water but instead, they push it.

Pool pumps create low pressure

We may call it suction but, technically speaking, the more descriptive term is a “partial vacuum.” Typically it is measured with a vacuum gauge that compares the difference between the higher air pressure outside the pump and lower-pressure inside the suction-side of the pump housing.

Inside the pump, the impeller spins, creating centrifugal forces that send water molecules away from the center of rotation. This is where the pushing takes place.

As the spinning impeller flings water molecules away, the space left behind causes a partial vacuum — suction — that extends into the pump strainer basket, suction pipe, all the way out to the drains and skimmers. This area of lower pressure allows the higher atmospheric pressure outside the suction system to push water molecules into the space created by the impeller.

When pump suction is restricted by small pipe, excessively long pipe runs, clogged drain covers, or dirty skimmer baskets, the partial vacuum can become (nearly) a full vacuum that vaporizes water, changing it from a liquid to a gas. This happens when the suction-side pressure drops below water’s “vapor pressure,” the transition point that also changes with water temperature. Hot water vaporizes — boils — at 212 degrees F.

In a pumping system, when the water vapor boundary is crossed, you can begin to hear the terrible pump noise called cavitation. The noise is actually the sound of water vapor bubbles collapsing as they move from the impeller’s suction side to its pressure side.

That sound you hear is the water changing back from a gas to a liquid. This happens so fast and with so much force that it can severely damage the pump’s impeller. It also generates heat and violent vibrations that damage pump bearings and seals.

Two Forces at work

To circulate water, two forces work together: Atmospheric pressure and the electrically driven pump.

These forces create suction-head pressure, which is the difference between the weight of air pushing down on the surface of the pool and the partial vacuum created by the electrical pump’s spinning impeller.

The maximum suction-head pressure available at sea level is 14.7 psi.

The pump impeller can only push water molecules as fast as they are delivered by atmospheric pressure. This explains why small suction-side piping, extra long runs, and elevated pumps aren’t as effective.

In-pool hydraulics

Understanding water must be pushed, not pulled, is equally important inside the pool itself.

Despite what legacy pool codes still say, main drains are not capable of “creating circulation throughout the pool.” In-pool circulation is “pushed” by the water entering the pool from the return fittings.

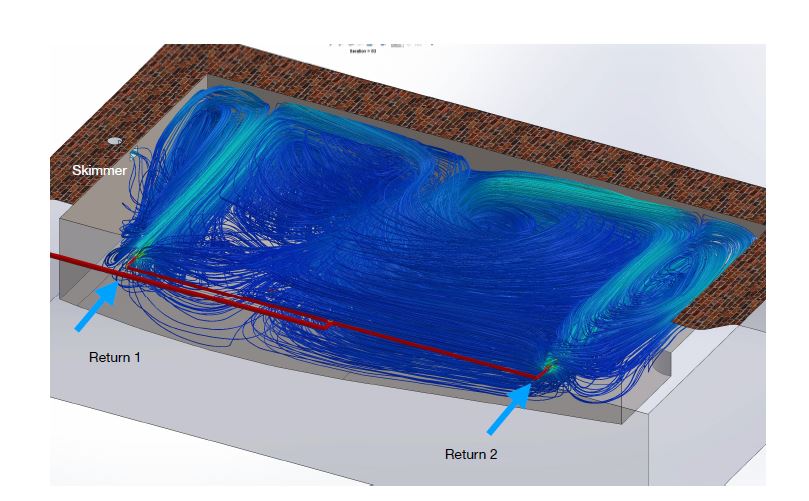

Look at the flow simulations done using Finite Element Analysis (FEA) software, the same kind of software that accurately predicts the aerodynamic performance of airplanes and race cars.

The 3D model on page 30 shows a 13,229-gallon pool measuring 15-by-30-by-5 feet. The results represent in-pool circulation patterns created by two 1-inch-diameter return nozzles symmetrically spaced around the pool.

The multi-colored lines indicate the flow path that 50 different “water molecules” took as they traveled through the piping and around the pool. Notice how they are “pushed” by the return inlets and the currents until they pass close enough — within about 2 feet — of the skimmer and drains to exit the pool.

Red (in the piping) indicates a water velocity of approximately 6 feet per second (fps). The teal in front of the returns indicates water moving around 1 to 1.5 fps. The darker blue lines are slow-moving currents — 1 to 2 inches per second (note inches, not feet).

Analysis 1: This shows two 1-inch returns, two 9-inch square drains, and one standard skimmer. The returns are diagonally offset to drive the circular pattern. Notice the dead spots near the center of rotation. This is where debris settles because the water is moving too slowly to keep it in suspension. Also notice dead spots in the corners and around the steps where debris collects and algae is more likely to grow.

Analysis 2: This simulation uses the same flow rate and white goods as before, except the returns were moved to one side of the pool. This effectively addresses the stagnant water around the steps and debris collecting in the center of the pool, but the deep-end circulation suffers. This is because there are no returns “pushing water” into this area.

The other factor is the effect of deeper water as compared to the shallow water, especially around the steps. The returns are hydraulically balanced and perform nominally the same, so we know that the difference between the shallow-end and deep-end circulation is caused by the pool geometry. This is why return fittings come in different sizes and styles (standard eyeballs, slots, down jets, wall washers, etc.). Manufactures make these variations for the same reason fancy garden hose nozzle have so many different spray patterns. Each one is designed to do a different job.

Conclusion

Understanding the science behind moving water is key to managing proper hydraulics inside pipe as well as in the pool itself.

Some laws — physics — can’t be broken. Understanding them is the only option.