Going with the flow means assuming everything is fine, letting the current take you away, and not rocking the boat. But using uncertified flow meter products creates risks and a false sense of security that can get you into hot water. Stay cool, play it smart, and make sure your flow meter is tested and certified by NSF. Due to concerns with water safety and accurately measuring flow rate, NSF now has a program to evaluate, test and certify flow meters for their important safety and functional aspects.

NSF/ANSI Standard 50: Equipment for Pools, Spas, Hot Tubs and Other Recreational Water Facilities applies to most products used at a pool, spa or water park. For example, the following products have specific sections and requirements within NSF/ANSI 50:

• Pool alarms

• Pool and spa covers

• Safety Vacuum Release Systems

• Suction fittings and drains

• Filters

• Pumps

• Valves and fittings

• Piping

• Skimmers, grates and overflows

• Chemical generators

• Chemical feeders

• UV and ozone systems

• Ionizers

• Automatic controllers

• Water quality testing devices

NSF International developed NSF/ANSI Standard 50 through a consensus process with balanced input from the regulatory, industry, academic, and consumer communities. The standard continues to grow and evolve with the addition of appropriate functional evaluation criteria for different products which may not already have a detailed chapter or section within NSF/ANSI 50. One example of the ongoing need involves measuring flow rate, which is critical to water safety from many different perspectives. If the system flow rate is incorrect, damage may occur to the piping, valves, filtration and circulation equipment or create human safety risks.

For instance, water flowing at too high of a rate may cause channeling in a sand filter. When channeling occurs, the water bores a short circuit path through the filter media bed and affects performance. This can lead to cloudy and oily water.

Another way in which high flow rates can cause harm is through a suction fitting. Suction fittings, or drains, are certified to perform safely at or below a certain flow rate. If the system flow rate is higher than the certified maximum flow rating of the suction fitting, unsafe levels of force may be generated at the suction fitting leading to entrapment and death.

Low flow rates create other serious health and safety risks. If the flow rate is too low but the facility staff are unaware of it, they can unwittingly create serious health risks for the swimmers. Too low a flow creates dead-zones within the pool or spa where the water is not properly disinfected, creating a risk of fungal, viral, and bacterial incidents and outbreaks. Some filters require a particular minimum flow rate to function properly. The filtration process of contaminant catchment and removal can seriously drop when circulating water at too low a flow rate, leading to cloudy water and compromised safety.

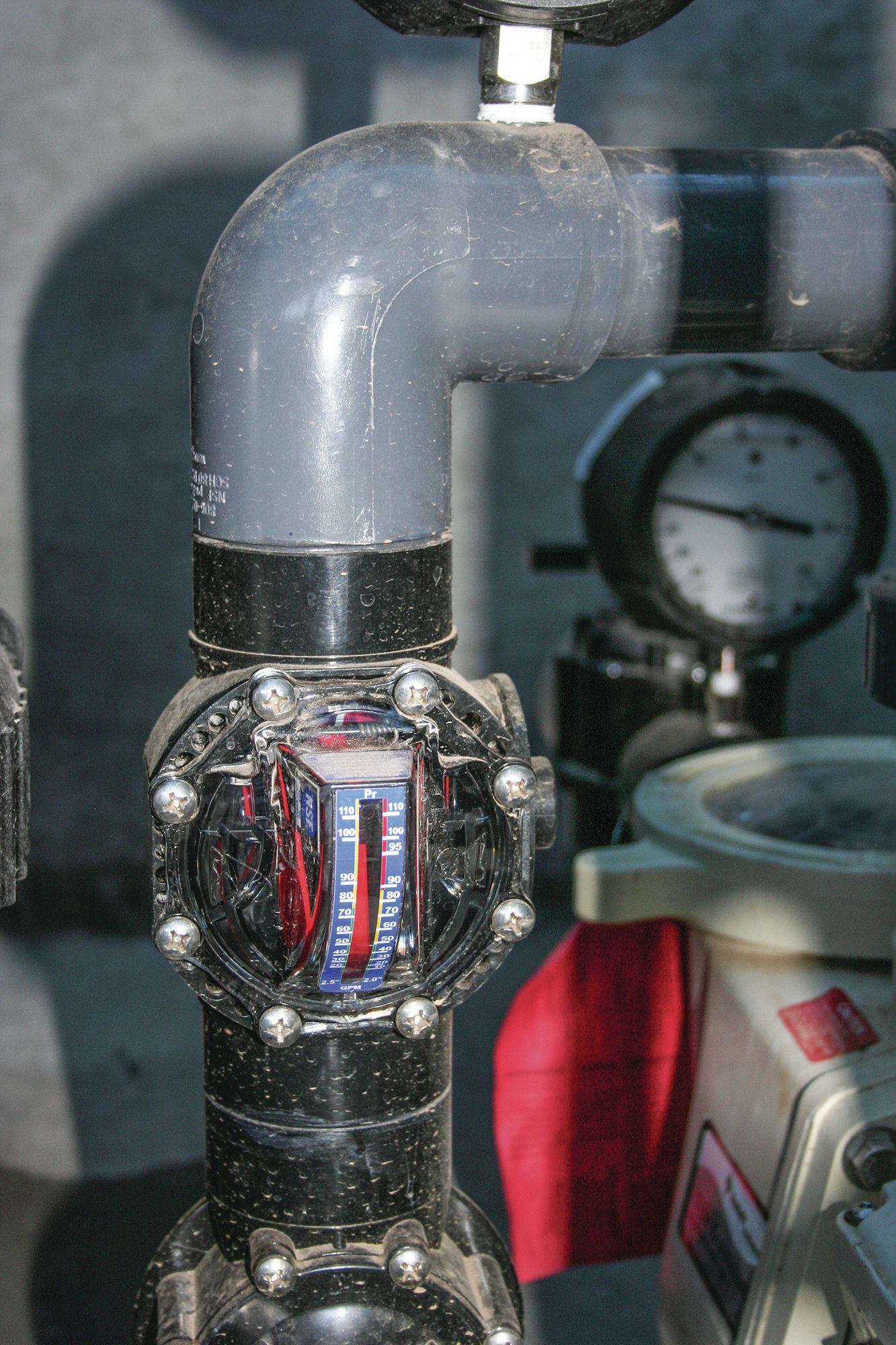

Verifying the safety and effectiveness of flow meters has become more important because they play a key role in proper disinfection. They also prevent water flow rates from exceeding safe limits as defined by the Virginia Graeme Baker Pool and Spa Safety Act, a law designed to prevent drain entrapment. Because the pump/motor speed can be changed when using variable speed pumps or an external frequency drive, it is even more important to use certified flow meters to properly manage flow rate.

Pool and spa operators, along with public health and building officials, have all noted that correct flow meter performance is critical to pool and spa safety. State laws require that public pools install a flow meter to ensure that health officials can verify conditions during an inspection. For example, regulations recently enacted in California require a 10 percent accuracy of flow meters and that circulation products are tested and certified to an industry standard (such as NSF/ANSI 50).

For all the reasons above, NSF created detailed and rigorous evaluation and testing criteria for flow measurement devices. The NSF criteria categorizes the level of performance and accuracy of the flow meter product. NSF certified flow meters are also listed in NSF’s online database, enabling users to find flow meters that have been independently tested and certified.

In order for a flow meter to earn NSF/ANSI 50 certification, it must be evaluated by NSF staff and engineers. The work scope includes verification of water contact material safety to determine if materials may leach out harmful contaminants or colorants, evaluation for material corrosion resistance and dissimilar materials, and tests of fastener strength.

Because products placed into the piping system are under pressure, flow meter products are tested in a series of different pressure tests beginning with a sustained burst pressure at one and a half times the manufacturer’s claimed working pressure. Next, a cyclical pressure test of 20,000 cycles of pressure being increased from zero to 30 psi verifies the durability of the product design and fasteners. After the cyclic test, the device is exposed to twice the manufacturer’s claimed working pressure. Finally, the unit is evaluated for ultimate burst strength of at least four times the manufacturer’s rated pressure.

Flow meters being installed within the waterway are tested for head loss or pumping loss with each of the manufacturer’s recommended piping diameters. This provides important data for pool designers and operators so that they may account for system resistance requirements in pump and filter sizing.

A critical factor of flow meter evaluation is the accuracy test, which is conducted at multiple flow rates. The flow meter is tested with the manufacturer’s recommended pipe size(s) and installation orientation under at least eight different data points across the manufacturer’s recommended range of operation. Testing at NSF with different piping configurations, such as long straight runs and elbow fittings closely mounted to the flow meter, helps to ensure accurate performance when the flow meter is used in the field.

In addition, NSF evaluates the manufacturer’s installation and use instructions to determine which testing conditions for flow rate must be conducted. NSF reviews product marking and/or the data plate for accuracy. Lastly, NSF conducts an audit of the flow meter manufacturing facility to verify quality assurance requirements are being met, and that only authorized materials are used in the manufacturing of the flow meters. To ensure ongoing compliance, NSF conducts annual unannounced facility audits and periodic retesting.