The prevalence of UV water treatment is growing in commercial pool applications throughout the U.S.

Installing a UV-C system at a commercial aquatics facility will lower chemical usage by up to 30- to 50 percent and achieve safer water by eliminating pathogens, viruses and chloramines. In addition, the reduced chloramines will improve the air quality around the pool, especially for indoor facilities. This article will cover the selection of UV-C systems, as well as their installation and maintenance.

Getting started

UV sanitizers offer plenty of unique benefits. However, there are different types, and the proper unit should be selected for specific aquatics applications. In particular, it is important to match the unit size to the pool or waterfeature type — for example, splashpad, play structure, lazy river, etc. Pool professionals who understand the differences can easily determine which unit to recommend.

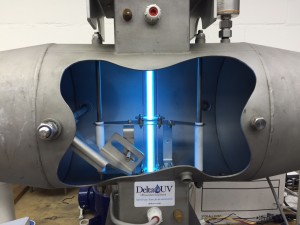

There are two types of UV lamps. First, there are low-pressure, high-output lamps, which emit UV rays at 254 nanometers. On the other hand, medium-pressure lamps emit UV rays between 200- and 600 nm.

Low-pressure lamps are better suited for semicommercial and commercial applications with lower flow rates and light bather loads, while medium-pressure models are designed for large commercial installations with high flow rates and heavy bather loads. The differences between each lamp are cost, flow requirements and the ability to destroy chloramines (NH2Cl).

Medium-pressure lamps are commonly used for indoor pool applications because their large light spectral is more effective at reducing the health problems caused by nitrogen trichloride (i.e., chloramines), which have been linked to numerous pool closures due to poor indoor air quality.

For semicommercial applications such as hotels, motels or fitness facilities with flow rates more than 110 gallons per minute, a low-pressure, high-output UV system, or an amalgam unit designed to accommodate higher flow rates should be considered.

Selecting a UV-C sanitizer

UV-C systems are sized according to the gallons per minute generated through the filtration system, not the volume of water in the vessel. Bigger is not always better here. The gpm rating is based on lamp and vessel design along with a computational fluid dynamic computer simulation. The correct power rating for a commercial UV unit is 40 megajoules, based on the NSF/ANSI 50 standard. That is the point at which it will sterilize all pathogens found in pool water.

A UV-C unit will handle a range of flows. Manufacturers will produce each unit for a minimum and maximum flow in gpm. As an example, unit XYZ will handle 57 to 80 gpm. If the pool system’s flow rate exceeds the UV-C unit’s maximum gpm rating, the sanitizer cannot achieve the intended 99.9 percent single-organism sterilization. If the water flows through the UV vessel too quickly, the contact between the water column and the UV-C light in the chamber is not long enough to achieve sterilization.

Conversely, if the pool water flows too slowly, it stays in the light chamber too long, and some free chlorine photo-oxidation will occur, thereby increasing the amount of chlorine needed in the pool to achieve enough free chlorine residual.

All of the sterilization happens within the vessel, and UV-C does not leave a residual or create any corrosive gas. Another factor that should be considered when selecting a UV-C unit will be lamp life. UV-C lamps are rated in hours of service life, which is the period of time during which the lamp will produce enough millijoules of UV-C power to properly sanitize the single-cell organisms in the water. Lamp life typically ranges from 6,000 to 16,000 hours, which, in real-world terms, means there are lamps that have a 12-, 16- or 24-month service life. It’s beneficial to purchase a unit that is NSF 50 certified because many municipalities require this.

Installation procedures

UV-C units should be installed in line in the plumbing.

UV-C units must be placed after the filter, and particulate in the water can create a shadow effect inside the unit, between the lamp and any single-cell organism we are trying to sterilize.

If there is a heater in the system, the preferred location for the UV-C unit is before the heater. Using a UV-C unit will extend the life of the heater by removing chloramines, which are corrosive to the metal in the heat exchanger. Some equipment pads are tight, so if the UV-C unit must be installed after the heater, check with the manufacturer to ensure that the plastic used in that particular unit will handle hot water coming out of the heater.

The units should be installed with enough room for technicians or operators to perform lamp replacements and quartz-tube cleanings in the future. The glass lamp and quartz tubes cannot be bent, so it is important that there be enough space to remove them straight out of the UV system.

A typical pool with a UV-C unit also will include a chlorine feeder. This should be plumbed after the UV-C unit, typically last in line before the water returns to the pool.

UV systems can be easily added to an existing circulation system — again, after the filter and before other accessories such as heaters or chlorinators.

The unit should be plumbed in according to the manufacturer’s instructions so the UV system properly fills with water in relation to the unit’s flow rating.

Many professionals plumb in a bypass. This makes servicing and maintenance easier by allowing the operator or technician to separate the UV system when necessary, especially during winterization. Because the UV lamp and quartz tube are made of glass, they must be brought inside to avoid winter damage, such as freezing, when the pool is not being used. This applies to outdoor commercial pools that might close in the winter.