We can all picture a teenage lifeguard kneeling on the pool deck using a DPD kit and color comparator to check the pool water chemistry.

The lifeguard is trained on how to use the test kit and assumes it works and is accurate. But what if the test reading is incorrect? Inaccurate readings can lead to excessive chemical use, which is costly and makes it more difficult to keep the chemistry in line. How can the lifeguard and other users be sure testing equipment produces accurate and repeatable results? With accurate, real-time information and the proper equipment, the pool chemistry can be kept in balance.

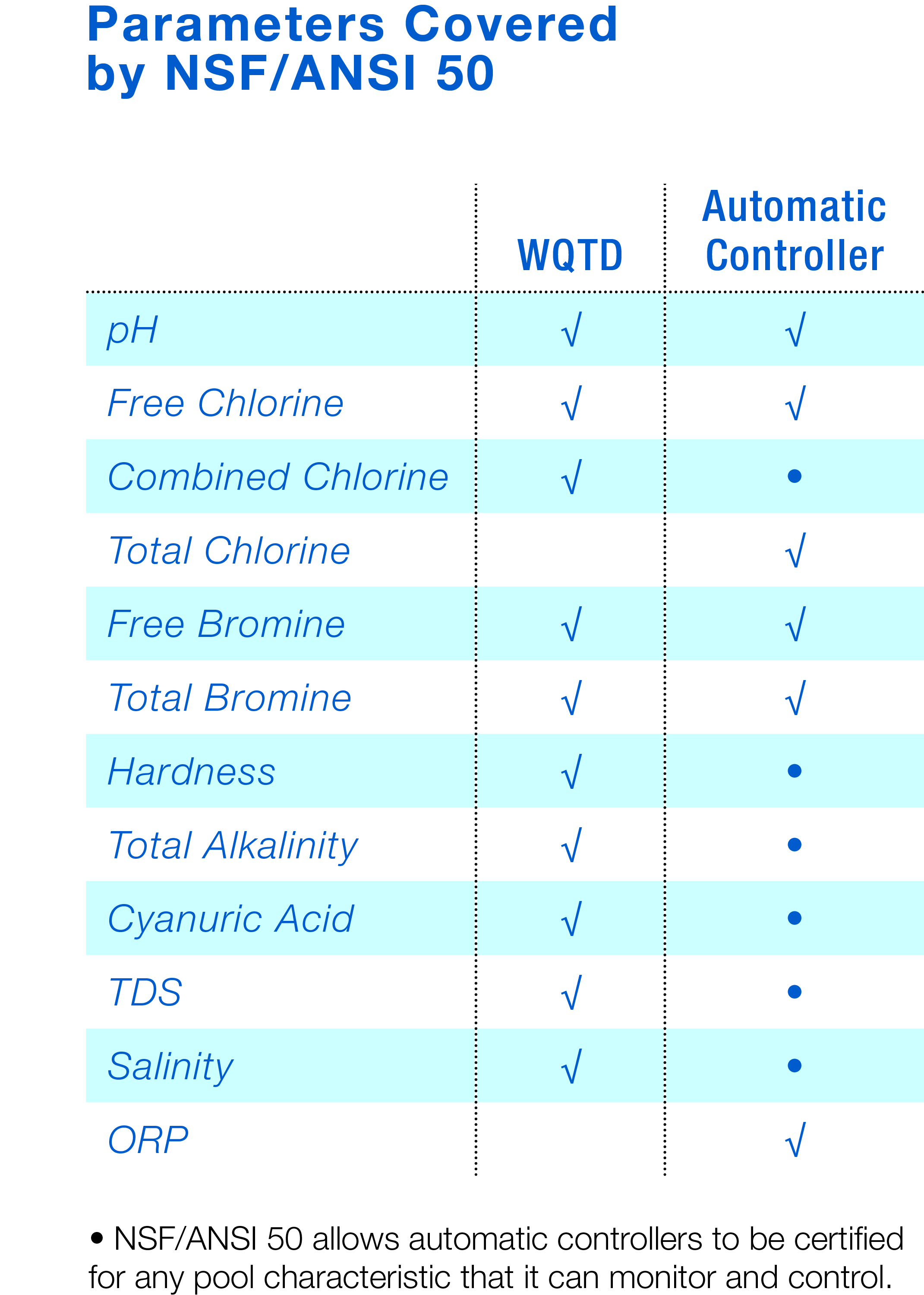

Third-party certification to NSF/ANSI 50 allows manufacturers to make verified claims about the performance, accuracy and operating range of their water-quality testing devices (WQTDs). It allows consumers to make apples-to-apples comparisons between products and provides confidence that the test device will work at the end of the shelf life indicated by the manufacturer.

Third-party certification of water-quality test devices includes a review of water contact materials for health effects, monitoring audit(s) of production locations and product performance verification testing. The performance testing of a WQTD involves accuracy and repeatability testing on two different lots of new production, which are tested multiple times on two different days. Unlike most NSF/ANSI 50 certifications, WQTDs require follow-up testing of the product at the end of the manufacturer’s specified shelf life. This is a follow-up performance test on product that has been opened and stored, in order to mimic actual product use. The original two lots are retested for accuracy at the end of the manufacturer’s claimed product shelf life. The accuracy testing verifies the water-quality test device accuracy claim. Certified products are given an accuracy rating to one of three levels: L1, L2 or L3, with L1 being the highest accuracy rating.

Many use “smart devices,” such as automatic controllers utilizing pool chemistry information, to directly control the operation of pool equipment.

Automatic controllers utilize sensors and probes to measure water parameters, such as temperature and free chlorine, to turn equipment on or off based on defined setpoints. The Model Aquatic Health Code requires automatic controllers to be third-party certified to NSF/ANSI 50. Certification requirements for automatic controllers are similar to WQTDs and require accuracy, repeatability and life testing, which is analogous to the WQTD shelf-life test.

Automatic controllers also undergo chemical resistance testing, setpoint actuation testing and operational protection testing to verify the accuracy of the readings and that the controller is able to correctly turn equipment on and off based on those water readings. NSF/ANSI 50 does not have L1, L2 or L3 accuracy ratings for automatic controllers, which all must meet the same minimum level of accuracy based on the specific parameter being tested. Automatic controllers can be certified for pH, ORP, FAC/total chlorine and free/total bromine, but NSF/ANSI 50 allows for the testing of additional parameters.

When using NSF/ANSI 50-certified test devices and controllers, that teenage lifeguard can be confident in the safety of the pool and quality of the water. With accurate information and chemistry control, he or she can handle any situation that jumps into the pool.