Every builder has dealt with the frustration that pump-priming challenges can add to design. Builder and civil engineer Mark Dorsey was struggling with this issue when he came upon an idea.

He was working on a camp for a Christian organization that ministers to high schoolers. The project involved three pools on the side of a steep mountain in the Colorado Rockies. The mountain site had a steep elevation change.

“I was working on the conceptual design and trying to save the camp substantial costs by reducing the retaining-wall heights,” says Dorsey, owner of Medallion Pool Co. in Asheville, N.C. “We needed retaining walls of upwards of 22 feet to make this project work, and I wanted to reduce the retaining-wall heights by terracing between the three bodies of water. But there wasn’t an option to move the equipment room.”

Like most builders, he was hesitant to place the pump more than 2 feet above the pool, knowing that it can be difficult for pumps to pull water up more than that distance. He worried the pump would fail to prime reliably.

As he and his structural engineer tried to come up with the best solution, “I said, ‘Why in the world have we not solved this problem of priming a pool pump?’” he says. “And it hit me. I thought, ‘Here’s an opportunity. I think I can solve this.’”

After more than two years of research and testing, Dorsey is preparing to roll out a product meant to solve this problem, thereby entering him into the manufacturing realm.

Learning the landscape

Dorsey was looking for a solution that is simple, automated, easy to install and cost-efficient.

In performing his research, he learned that just about every other industry that moves fluid has a solution to this issue. However, because pools and their needs are different, none would work.

Pool pumps can’t lift water very far because the impeller doesn’t touch the internal housing, or volute, on the sides, so it’s not sealed and can’t create a vacuum.

The rotary vein pumps used in other applications, such as on tanker fire trucks, do feature impellers that seal against the side, but that friction requires regular oiling, which would introduce oil into the pool or spa. So those options couldn’t be adapted to the needs of pools and spas.

Landing on a solution

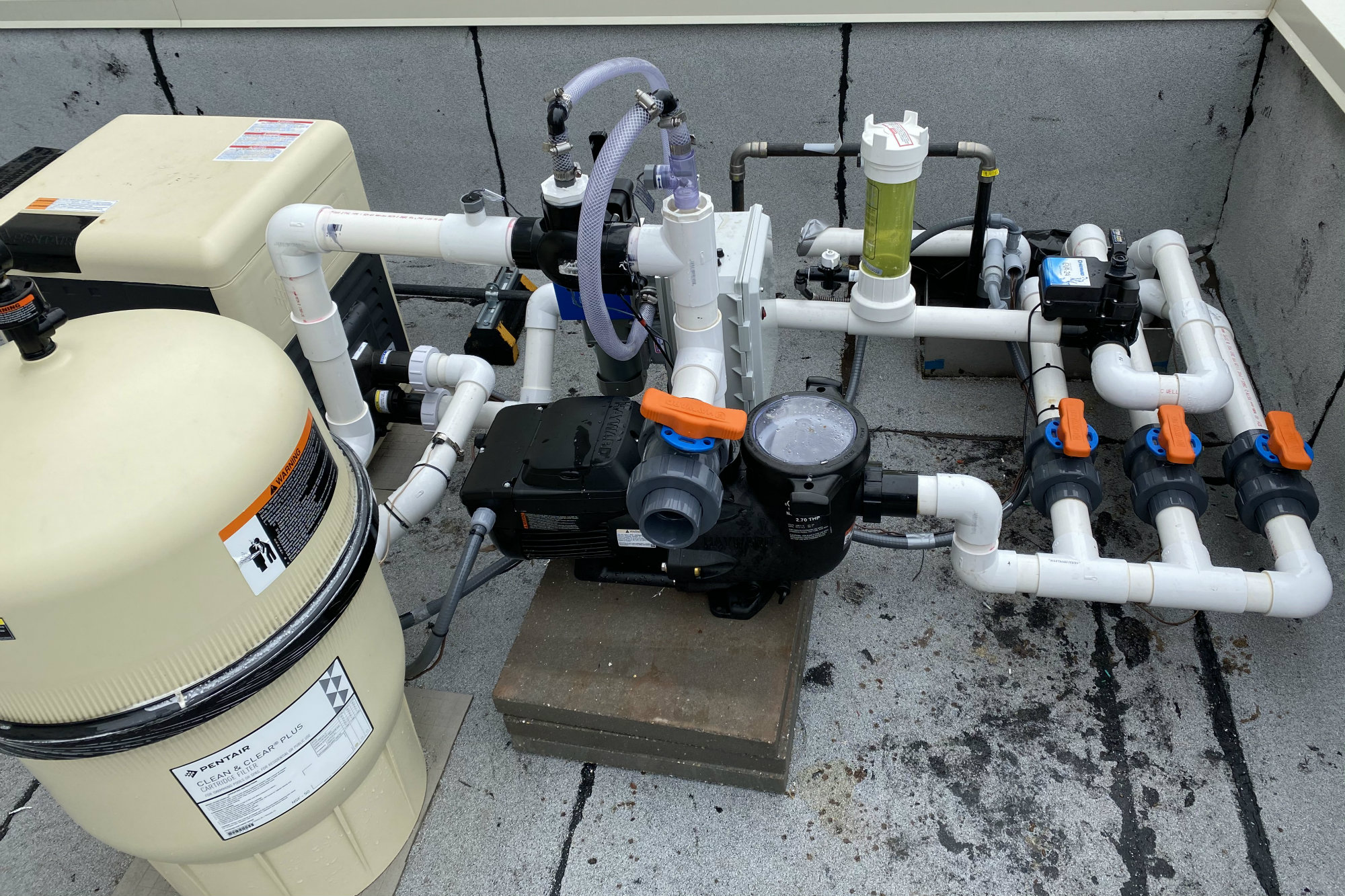

For his invention, called Primeology Systems, Dorsey chose a highly specialized diaphragm pump, finding these systems efficient, simple and inexpensive. This is the backbone of the invention.

“It has the ability to produce a pretty high vacuum and can move enough water so that the time to prime is more than sufficient,” Dorsey says.

The standard system can accommodate 16 feet of elevation difference between the equipment and water surface. By changing the diaphragm pump, Dorsey can scale the system for larger applications such as waterparks and commercial pools.

The system includes a computerized controller and flow sensors to prime the pump upon when activated.

“As the pump starts, we close a valve on the outlet side of the pump, and establish a vacuum until we pull water up through the pump,” he says. “The secret is that the impeller is flooded. When the impeller in the pump is completely surrounded and maintains water, instead of air, it moves the water.”

The Primeology unit constantly monitors the system and will shut the pump off if it loses prime.

The system was tested in different scenarios to learn how it works with automation and in different applications. It will work with automation, variable-speed or single-speed pumps, and on new or existing pools, Dorsey says.

Through continued testing, he has verified that, with customization, the device will lift water up to approximately 25 feet. This is the maximum elevation before the available net positive suction head (NPSH) falls below what’s required, Dorsey says.

Various applications

Dorsey expects this system to solve a number of problems that builders face.

Particularly in neighborhoods near bodies of water, flood zones have become an issue. As increasingly brutal storms have hit certain parts of the country, more local regulators are beginning to require that pool equipment be placed above the flood zone to protect it during a storm. This leaves some builders having to choose between building a waterproof vault, which adds considerable cost to the project, or finding ways to deal with the challenge of priming a pump in these situations.

The device also could be used for vanishing-edge or perimeter-overflow applications that rely on a remote surge tank and currently would require an underground vault for equipment in many cases, Dorsey added.

This device also eliminates the need to keep a pump running constantly, which some builders and service techs will do if the pump sits very far above the water, for fear that repriming the pump would require extreme amounts of time. This could result in energy savings, Dorsey says.